Big Booms for the Big Build: A Closer Look at the West Gate Tunnel Project

Case Study

Once completed, twin tunnels under the suburb of Yarraville (between the West Gate Freeway and the Maribyrnong River) will deliver a vital alternative to the West Gate Bridge, removing thousands of trucks off residential streets and providing quicker and safer journeys for commuters.

The project is a partnership between the Victorian Government and Transurban and is being built by a joint venture of CPB and John Holland.

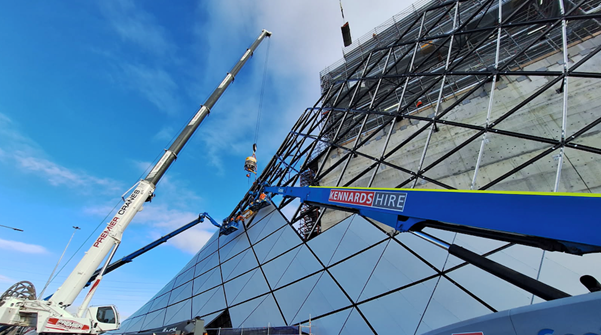

The project design includes unique steel structures over the vehicle entry and exit points (also known as portals) at both the southern and northern ends of the tunnels, and the ventilation buildings. The structures are designed to create a lasting visual impression for the millions of commuters using the tunnels each year.

The steel structures are built on the job site, around 100 meters away from where they’ll finally be fixed to the portal structure. Two cranes are used to move each piece into place: one crane picks up the pieces from where they’ve been built and transfers them to another crane mid-air, where they’re moved into place up to 50 metres (approximately 160 feet) above ground and bolted to the structure.

That’s where CPB John Holland Site Superintendent, Unakea Taiki (JJ), required some of the biggest boom lifts available in Australia to reach the top of the structures.

With Kennards Hire already supplying much of the access equipment onsite – plus crib sheds, power tools and other smaller equipment – JJ invited them to pitch for the additional EWPs, including two x 215ft boom lifts, 10 x 180ft boom lifts and two x 135ft boom lifts.

The 180ft boom lifts facilitate the mid-air transfer of the structures and are then used to bolt the structures to the portals. The project has also recently received two 215ft boom lifts to position and fix the structures over the ventilation building, at a height of more than 60 metres (approximately 200 feet).

“Whenever I need equipment, Kennards Hire have delivered it then and there, no questions asked,” says JJ. “With the great service we’ve already received, asking them to quote for this job was a ‘no brainer’.”

“We were very transparent with our quote – there were no hidden costs or any hidden agendas,” says Cody. “We knew we could supply the equipment and provide training but what gave us a point of differentiation was offering a dedicated project manager to the project.”

That project manager was Richard Impey, who had already established good relationships on the WGTP site, especially around Kennards Hire’s capabilities, service and support.

“Richard gave them a single point of contact and the confidence that we had the ability to deliver on what we said we were going to deliver, especially with regard to this specialised access equipment,” says Cody.

“From the customer's perspective, we were honest and upfront about costs and delivery, had the backing of our national Kennards Hire network, a demonstrated reputation for quality equipment and could provide expert project management support onsite.”

For JJ, the ability to supply the biggest boom lifts in the country was the priority, however so too was Kennards Hire’s service and support capabilities, and training for the project’s boom lift operators.

“Richard is onsite every week to check on the equipment and the project,” says JJ. “I'll give him unrealistic deadlines, where I need a piece of equipment in the next hour or two and it’s always been supplied. If there’s an issue with anything, I know I can call him and someone will be there within the next half an hour.”

Kennards Hire also provides a round-the-clock on-call service. “With the project operating 24 x 7, down time is not an option,” says JJ. “It’s critical to know there’s someone from Kennards Hire available at all times to solve our problems should anything arise,” he says. “It’s really good.”

“We’re on multi-million dollar projects and when we want something, we want it now,” says JJ. “At the moment, Kennards Hire is the only one providing that level of service. So what I’d say to other hire equipment suppliers is if you want to be on the same page as Kennards Hire, your service needs to be top notch.”

Learn more about Kennards Major Projects here