Knowledge is Power for Electrical Veteran Paul Nicholson

Get Inspired

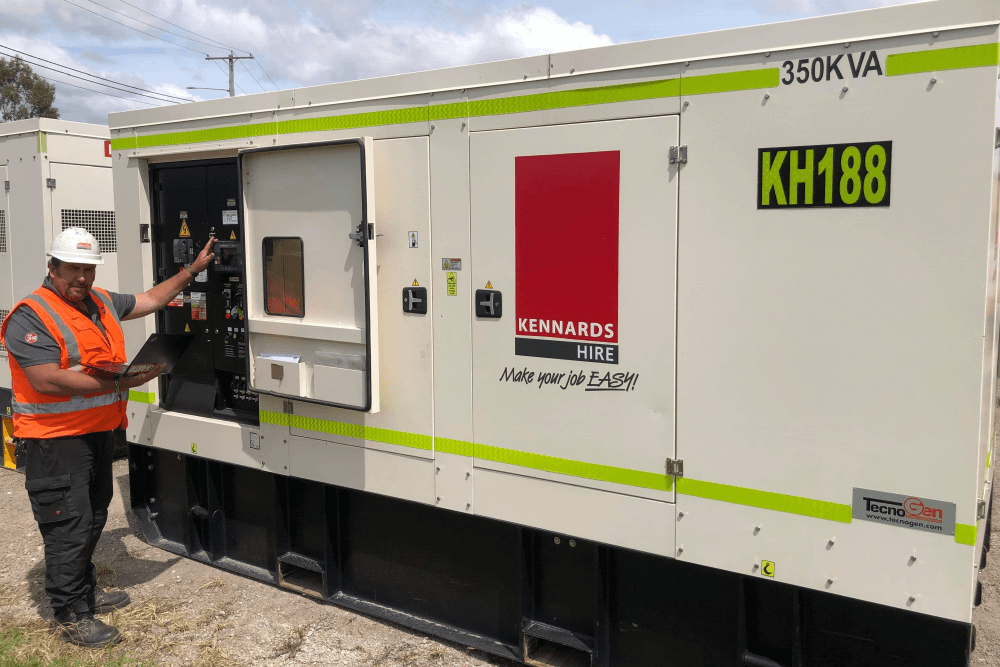

These days, as a Kennards Hire’s power specialist, he could find himself working down a mine in the outback or devising a power solution for a major utility company in the Sydney CBD.

Paul started as an electrical fitter and mechanic working in the domestic and commercial world before moving into the mining industry and eventually specialising in generators.

When he joined Kennards Hire four and a half years ago, he brought detailed knowledge of the power requirements of mine operations. His current position as power product specialist combines a sales role with an operational role.

Designing power solutions for the mining sector

Of course, there are the usual emergency calls, at any time of the day or night, but much of his work is designing power solutions. He spends a lot of time on the road meeting customers and inspecting the mine sites to understand what’s required and offering the most cost-effective solution.

On larger projects, Kennards Hire offers a turn-key solution that gives the customer one point of contact from the start to finish. Paul goes to the site, sets up the equipment and commissions it, before handing over to the customer. He also supervises its maintenance over the life of the project.

In 2019, when a NSW mining company asked Kennards Hire to quote on supplying 1000V of underground power, up to 1km inside the mine, he recommended using two 1250KVA generators and a 1.5MVA step-up transformer at 415-1000 volts.

Paul was inducted on the site so he could supervise the installation of the units at the mine surface and deal with any teething problems.

“We had built some redundancy into the system so the power didn’t drop out or let them down at any stage.”

The system has been operating successfully for 18 months and Kennards Hire is now working with the customer to extend the power further underground.

Most interesting job

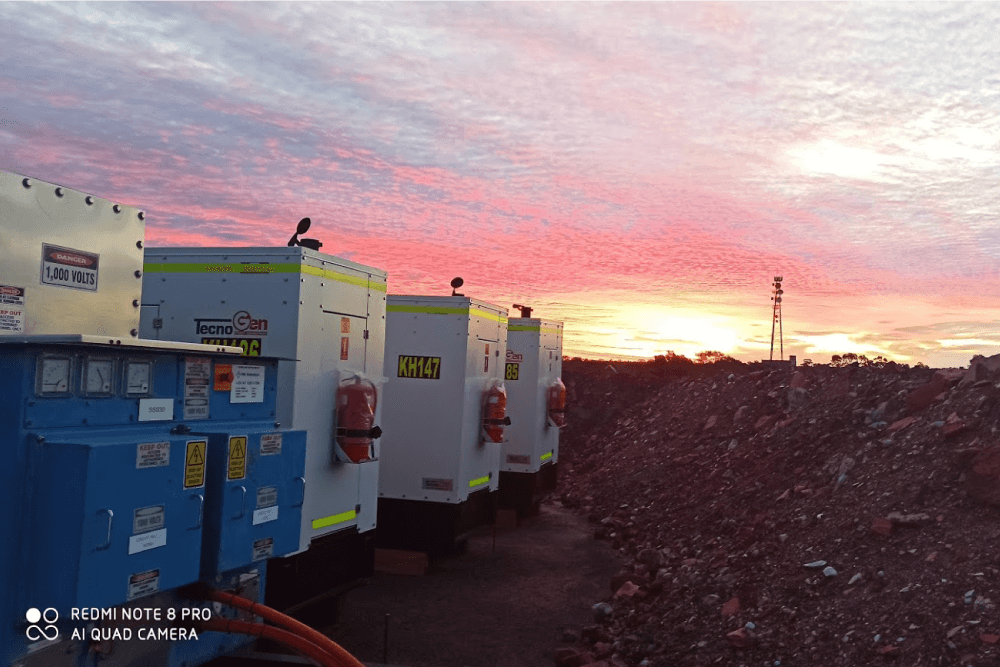

In early 2020, another mining company asked Kennards Hire to supply an 800KVA generator at 1000 volts to run their underground equipment.

Using fuel burn calculations, Paul showed them that using three 250KVA generators in a synchronised system would improve the fuel economy (over one big unit) and result in major savings.

“They need a lot of power to start motors but once the motors are up and running the power required drops right away," he said.

"That means at any given time, there’s a large amount of unused capacity in an 800KVA generator.”

The Kennards Hire team designed a load-sharing program that turned off one or two of the generators as the power demand decreased.

Over a year on-site, the three-generator system saved the company several hundred thousand dollars without compromising on power output.