Problem-Solving Pump Specialist Rises to the Challenge

Get Inspired

Every day brings a fresh challenge for Abdul Nasir - and that’s the way the Kennards Hire pump specialist likes it!

“I like coming up with solutions,” he says. “I like meeting people, understanding what they need, then making it happen.”

His appointment in 2019 to the role of Operations Manager, Specialist Pumps, for the NSW pumps branch was a kind of homecoming for Abdul. He had worked part time in Kennards Hire’s as a university student, and was impressed with what he saw.

“I like the company’s values. The training is excellent and there is so much support from staff and management to get the job done.”

Now he works with a range of customers, from self-employed tradies and DIYers to large construction companies, councils and utility companies, advising on the specialist pumps they need to meet their requirements.

He says there is no telling what the next phone call will be about. Soon after he started in his role, he was asked to create a water screen for an illuminated animation in Penrith Council’s 2019 REAL Festival. It took four pumps and a fair amount of trial and error to create the area required for the animation to work.

“It was a great learning experience,” he says. “I think that sort of challenge keeps the mind sharp.”

Most challenging job

In late 2019, Abdul was contacted by a company commissioned to run maintenance on a sewage treatment pond. They needed to divert up to 600 litres a second of sewage from the pond each night for about two weeks while their engineers carried out the maintenance.

Abdul could see that access was difficult. Heavy equipment would have to be trucked in then forklifted into place. And his customer explained that sewage would have to be pumped to two discharge points at different levels.

Abdul drew a site plan and designed the pumping system.

A suction line from the pond led to six skid-mounted pumps – two 8-inch and four 6-inch – set up around the perimeter of the pond. Each pump was fitted with a 6-inch Y piece to accommodate the two discharge points, which were fitted with isolation valves.

The pump operation would vary according to the flow. At 600 litres per second, all the pumps would be activated. In low flow conditions, some of the pumps would be deactivated.

He drew a diagram to show how his customer how it would all work. Once it was approved, the valves were pre-built with the Y pieces in the Kennards Hire workshop.

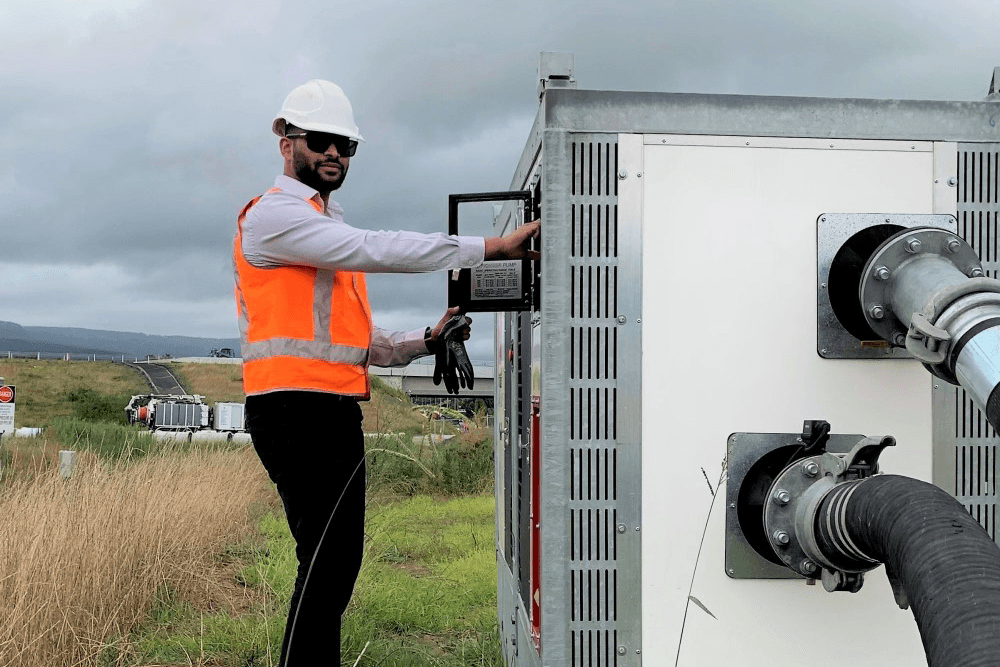

On the set-up day, Abdul and a Kennards Hire pump technician were on site to mobilise and test the pumps, hoses and isolation valves before handing over to the client.

Two weeks later, the job was finished, and they returned to demobilise the equipment and clean up the site.

“The client was very happy with how it went,” Abdul says, “and so was I!”